19 Apr 2025

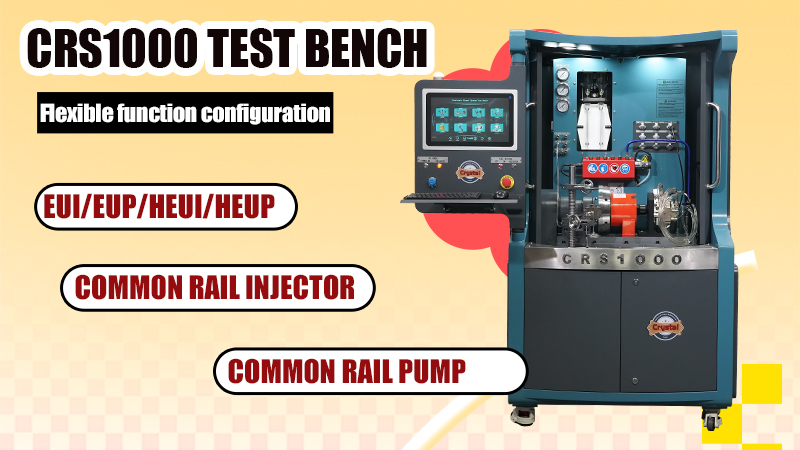

In the field of diesel engine maintenance and testing, the detection equipment of the high-pressure common rail system is crucial. The CRS1000 series common rail test bench has become a very cost-effective choice on the market with its excellent performance and flexible configuration. This article will analyze the ten advantages of the CRS1000 test bench in detail to help you understand why it can meet diverse testing needs.

1.Compact design and space saving. The CRS1000 CRS1000 adopts a unique appearance design and a small size, which greatly saves working space. For maintenance workshops or laboratories, small equipment footprint means higher space utilization and more flexible equipment layout.

2. High-configuration industrial integrated machine, stable operation. The test bench is equipped with a high-configuration industrial integrated machine, which is not only stable in operation, but also has a large storage space. It can efficiently process complex test data and ensure long-term reliability.

3. High-end materials, durable. The selection of stainless steel countertops and stainless steel fuel tanks improves the corrosion resistance and durability of the equipment, ensuring that it can maintain a long service life in harsh working environments.

4. Flexible host configuration, cost saving. CRS1000 provides three mainframe configurations: 4KW, 5.5KW, and 7.5KW. Users can choose according to actual needs to avoid waste of resources and effectively control procurement costs.

5. High-torque drive system to meet test needs. The spindle is driven by high-strength synchronous belts and high-precision reduction synchronous pulleys to greatly increase the output torque, ensuring that the equipment can cope with various high-load test scenarios.

6. Three-stage low-pressure oil circuit filtration to ensure oil cleanliness. The low-pressure oil circuit adopts a three-stage filtration system with a filtration accuracy of up to 3-5μm, which effectively prevents impurities from entering the test system and ensures the accuracy of the test results.

7. Cast iron structure, stable and reliable operation. The design of the cast iron workbench and cast iron spindle box enhances the overall rigidity and shock absorption performance of the equipment, making the operation more stable and suitable for long-term high-intensity work.

8. Universal high-pressure injector fixture, convenient clamping. The new universal high-pressure common rail injector fixture is humanized in design, fast and firm clamping, greatly improving test efficiency and reducing operation time.

9. Powerful operating system and data testing functions. CRS1000 is equipped with a powerful operating system that supports comprehensive test data collection and analysis, helping users to accurately diagnose injection system problems.

10. Independently developed control motherboard and high-precision measurement system. The use of independently developed multifunctional control motherboard ensures stable and reliable equipment operation; the high-precision measurement system ensures the accuracy of test data and provides a reliable basis for maintenance and research and development.

The CRS1000 series common rail test bench has become the cost-effective choice in the field of high-pressure common rail system testing with its compact design, high-end materials, flexible configuration and precise testing capabilities. Whether it is testing injectors and oil pumps alone, or testing multiple components in combination, it can complete the task efficiently and is an ideal choice for maintenance companies, testing agencies and research and development units.

Keywords: common rail test bench

Originally published 19 Apr 2025, updated 19 Apr 2025.