19 Jun 2025

Diesel injectors perform the critical task of delivering fuel to an automobile’s fuel system, a function essential for effective combustion. Along with maintaining the vehicle’s diesel engine, it is important to carry out routine upkeep and servicing of the injectors.

Faulty or dirty diesel fuel injectors can often lead to high fuel consumption, lack of power, or excessive exhaust emissions. When dealing with diesel fuel injectors, it is essential to follow methodical steps each time, whether for troubleshooting, scheduled maintenance, or repairs

.When conducting a diesel injector check, the appropriate tools and diagnostic equipment should be used. Here are the basic steps:

Visual Inspection

The very first step in any diesel injector testing should be a simple examination for defects. Inspect the injector body for signs of wear, corrosion, or any leakage. Assess the injector connectors and seals for any visible damage.

Fuel Pressure Testing

Testing injectors diesel pressure will help you understand whether the proper amount of fuel is supplied to the respective injectors. A fuel pressure gauge is used to measure fuel pressure. Performance data should be based on the parameters provided in the car manufacturer’s manual. Flickering fuel pressure indicates a fault either with the injectors or the fuel pump.

Testing for Leaks

Diesel injectors can develop leaks, either internally or externally, which can cause poor fuel delivery. A diagnostic tool that measures the fuel return flow can help with internal leaks. If there is an excessive amount of fuel return, it could be caused by a leaked injector. External leakage is always noticeable and can be inspected visually.

Injector Spray Pattern

An injector tester can be used to check the spray pattern dispersion of the injector. The injected fuel should be dispersed as a fine mist from the injector. If the spray pattern is uneven, it indicates that the injector is either dirty or defective and needs proper servicing.

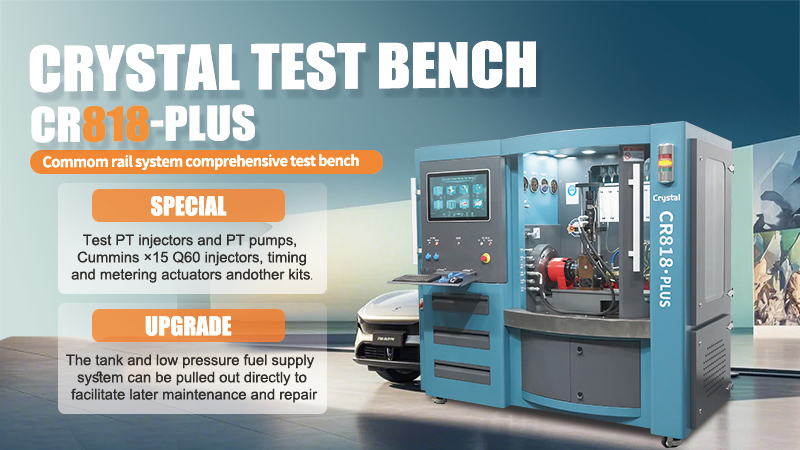

Although there are some basic tests and services that can be done by DIY mechanics, some injector problems demand more advanced diagnostic procedures. This is because professionals use diesel fuel injector common rail test bench, which enable them to make accurate diagnoses for the injectors.

Once a problem is diagnosed with the injector assemblies, the next step is to service the injectors. Whether cleaning, repair, or replacement is needed depends on the severity of the issue.

Cleaning Diesel Injectors

If the cause of the injector fault is due to wear or contamination, cleaning the injectors should be sufficient.

Repairing Diesel Injectors

Sometimes, defective injectors can be repaired instead of being replaced. In some cases, internal components can be replaced, allowing the injector to last longer. However, this process should be carried out by experts with the necessary experience and specialization.

Diesel Injector Replacement

If cleaning or repair does not resolve the issue, it may be necessary to replace the injectors. It is crucial to replace the injectors with OEM parts, as this will help enhance the equipment’s performance. This ensures identical performance in all the cylinders, and it is advisable to replace all the injectors simultaneously.

Keywords: common rail test bench

Originally published 19 Jun 2025, updated 19 Jun 2025.