02 Dec 2025

In today’s diesel engine industry—where common rail technology continues to evolve and precision is non-negotiable—only the most advanced, efficient, and intelligent diagnostic tools can meet the demands of professional workshops.

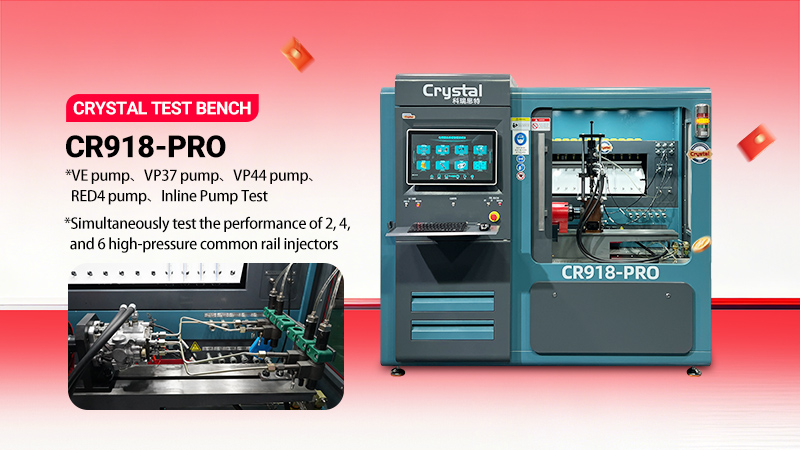

The Crystal CR918-PRO Multi-Functional common rail test bench was engineered precisely for this purpose.

This is not just another test bench—it is a complete diagnostic and calibration solution, designed to handle a wide spectrum of diesel injection systems with unmatched efficiency and accuracy.

With powerful hardware, intelligent control software, and modular expansion options, the CR918-PRO enables technicians to shorten testing time, improve workflow, and deliver consistently reliable results.

Why Choose the Crystal CR918-PRO? Because It Delivers What Others Can’t.

1. High-Pressure Single Common Rail Injector Testing (All Brands Supported) Powered by a stable high-pressure system and precision flow measurement technology, the CR918-PPRO provides comprehensive testing for Bosch, Delphi, Denso, Siemens/VDO, and more.

It performs:

Precise injection quantity measurement.

Back-leak testing.

Response and stability analysis.

Fully automated test sequences.

Every injector parameter is displayed with clarity and accuracy.

2. Automatic Generation of All Major Calibration Codes.

The CR918-PRO features an advanced coding algorithm capable of generating every commonly required calibration code, including: QR, IQA, IMA, ISA, c2i, c3i, and ICC (VD0).

This ensures seamless ECU communication and perfect injector integration after servicing or replacement.

3. Full High-Pressure Common Rail Pump Testing.

Simulating real engine operating conditions, the CR918-PRO evaluates pump performance through:

Maximum pressure output.

Internal leakage testing.

Pressure-holding stability.

Delivery rate analysis.

This ensures accurate diagnosis of pump health and reliability.

4. EUI & EUP Capability with EUS-H High-Performance Cam Box (Optional)

When paired with the EUS-H cam box, the CR918-PRO can test:

EUI (Electronic Unit Injector).

EUP (Electronic Unit Pump).

Greatly expanding your service coverage for trucks, heavy machinery, and industrial diesel engines.

5. Six-Cylinder Automatic Flip-Up Oil Collection System

Built for usability and durability:

Automatic flip-up mechanism.

Easy fuel disposal.

Convenient tank cleaning.

Supports multi-injector workflow.

Ideal for busy professional service centers.

6. High-Precision Flow Meter.

Accurate measurement is the foundation of reliable results.

The CR918-PRO’s precision flow meter delivers:

High repeatability.

Stable readings.

Traceable accuracy.

Crucial for both performance assessment and calibration code generation.

Constructed with a reinforced steel frame and premium industrial components, the CR918-PRO is built for continuous operation—perfect for workshops with heavy daily workloads.

CR918-PRO: A Smarter Investment for a More Profitable Workshop.

Expand Your Service Capabilities.

Test common rail injectors, pumps, EUI/EUP systems, and more.

Boost Productivity.

Automated operations + multi-injector capability = faster workflow.

Improve Repair Accuracy.

Deliver right-first-time results backed by precise measurement.

Reduce Equipment & Training Costs.

One multi-functional unit replaces multiple single-purpose benches.

Upgrade Your Workshop to the Next Level of Diesel Diagnostics.

Whether you want to increase your testing capacity, improve repair accuracy, or offer more advanced services, the Crystal CR918-PRO is the professional tool that transforms your workshop.

Keywords: common rail test bench

Originally published 02 Dec 2025, updated 02 Dec 2025.