19 Jan 2022

The fuel injector is the key component of the diesel engine. Its working quality directly affects the power, economy, emission and reliability of the diesel engine. According to the requirements for the formation and combustion of the mixture, the injector should have a certain injection pressure, injection stroke, and appropriate injection cone angle. In addition, the fuel injector should be able to quickly cut off the fuel supply when the fuel injection needs to be stopped, and the phenomenon of oil dripping will not occur.

Among the common injector failures are 1. Poor atomization of the injector, resulting in a drop in the power of the diesel engine, black smoke from the exhaust, and abnormal operation of the machine; 2. The needle valve is stuck, the engine power drops, jitters, and serious 3. The needle valve and the guide surface of the needle valve hole are worn out, the engine power is reduced, it may be difficult to start, or even impossible to start; 4. The fuel injector drips oil, when the temperature of the diesel engine is low, it is difficult to start, and white smoke is emitted; 5. The oil return amount is too high, so that the injection pressure is reduced, the injection time is delayed, the engine power is reduced, and even the diesel engine is turned off.

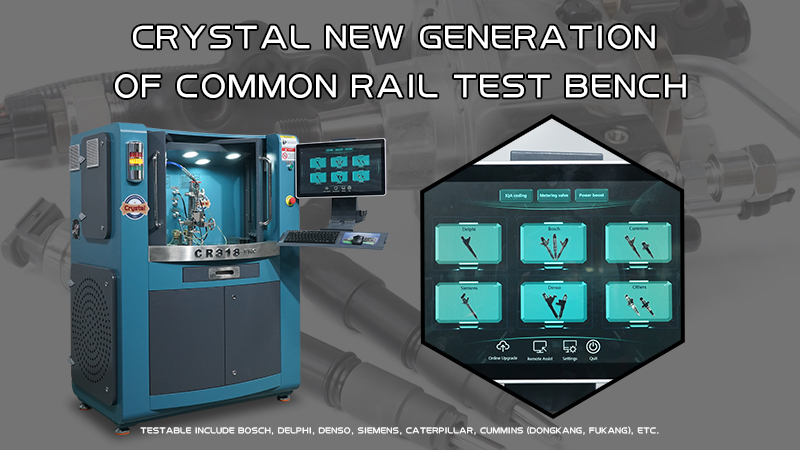

After the injector fails, it is necessary to use a professional common rail test bench for testing and maintenance. A professional common rail test bench can reflect the professional level of a repair shop. Crystal has been committed to the design and development of professional test benches. This time, we will bring you the introduction of Crystal's newly developed common rail test bench system.

The new fully automatic control system is firstly applied to CR318-Pro, a multi-touch industrial integrated machine interface with human-machine friendly design, which can rotate in multiple directions. It is easy to operate and has strong adaptability and built-in standard cones with more than 3500 fuel injectors data. The system can quickly complete the test of electronically controlled common rail injectors (including piezoelectric common rail injectors). The system can accurately test the high-pressure tightness, full-load fuel injection volume, fuel return volume, fuel injection volume at the discharge point, idle fuel injection volume, pre-injection volume, and pre-injection fuel return volume of the common rail injector. The fuel quantity correction code can be automatically generated during the test, and the system supports remote service and upgrade.

A simple text description is not enough to reflect its sense of technology. You can only experience it if you actually see it. You are welcome to watch the video of the new product on the Youtube Channel.

The new generation of control systems will be applied to comprehensive functional test benches such as CR708 and CR918 in 2022. The newly upgraded test bench model will also be named after PRO. The meaning of PRO in the CRYSTAL test bench will be a new control system, higher quality product components, an upgraded version of the test function and test accuracy, and a new product appearance.

At the same time, in order to establish a local market network, we sincerely recruit distributors from all over the world, so that we can actually cooperate and win-win on the basis of new products.

Keywords: common rail test bench

Originally published 19 Jan 2022, updated 19 Jan 2022.